Product code: SASUKI JUSTvision AD/MD

+ PRODUCT DESCRIPTION:

Machine vision inspection system JUSTvision

JUSTvision

JUSTvision machine vision inspection system is consisting of the high resolution, high speed, high performance standalone vision sensors, and the specialized utility software originally developed by Satsuki. It most remarkably works in dimensional measurement for the plane and side dimensions of extra-fine pitch precision connector continuous terminals etc.

All of product produced on the high-speed press processing line are inspected in line with high accuracy and high speed, also inspection data are collected in real time, its trend charts are displayed, and data to be saved.

Checking products for defects such as shape defects, scratches, foreign objects, etc., and also enabling history management of inspection data, it easy to achieve product traceability in quality control, preventing the outflow of defective products and improving productivity.

Inspection data are collected in real time, and the changes of data and its trend graph can be directly monitored, therefore it also useful as a maintenance utility for dies and press machine.

When combined with our automatic winder "MYTEL", all connectors can be inspected in line, and also all of measurement data (dimensions, statistics, failed images) to be saved in the computer, making quality control becomes easier.

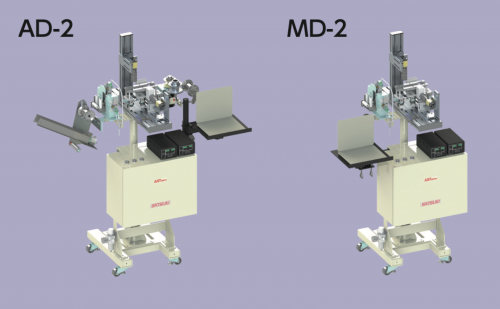

There are two types of machine vision devices: the AD type self-feed products with drive motor and the MD type separate-pull products without drive motor. The MD type is available as a type that is directly attached to the winding machine or as a stand-independent type.

Features

The standalone vision sensor integrates a high-speed, high-resolution camera, image processing, and communication functions, and comes standard with high-performance vision tools.

Easy to make a vision inspection application program just by the way of point-and-click.

By using a standalone vision sensor, in the case of ultra-high speed production line or a lot of inspection items required, that can be handled by increasing the numbers of vision sensors.

To meet the condition of high speed moving line, flash-emitting LED lighting with strobe power supply is standard equipped.

The laptop computer used to make vision inspection program, and perform monitor and collect inspection data in real time.

Equipped with a general-purpose guide jig as standard, enabling stable feeding and reducing the vibration, contribute to improve inspection accuracy.

By using an air blow unit (options), possible to remove oil and foreign objects adhering to the product, and enable to reduce misjudgments of inspection result.

Multiple devices (machine vision systems) can be centrally managed via LAN connection by a networked computer.

Specifications

| Item/Model | AD | MD |

|---|---|---|

| Driving motor | With | Without |

| Resolution (M Pixels) | 1.3, 2.3, 5.0 | |

| Numbers of camera | 2 | |

| Maximum inspection speed (parts/min) | 2400 | |

| Lens Type | C-Mount | |

| Lighting | Strobe LED light | |

| Computer | Laptop PC 1 unit | |

| Power consumption (kVA) | 0.4 | |

| Power source | Single phase AC100/200V 50/60Hz | |

| Ambient temperature (°C) | 0 to 45 (No condensation) | |

*For detailed specifications, please contact us separately.

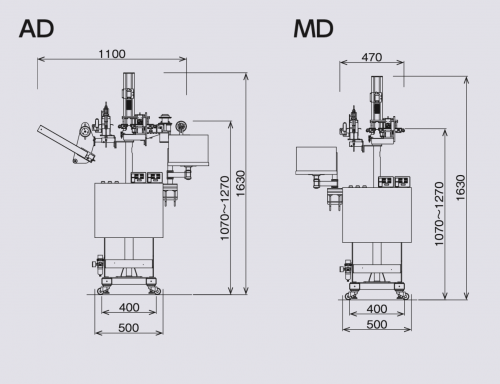

Dimensions

Vision sensor inspection data analyses system (software) IDAS-1 & IDAS-2

High-speed collecting image processing inspection data from vision sensors!

IDAS (Inspection Data Analyses System) utility software is designed for real-time monitoring of high-speed image processing inspection data from vision sensors, graph display, data storage and statistical analyses.

Via Ethernet, communication with the vision sensor has been achieved collecting data at high speed.

As the dedicated software, IDAS-1 is corresponding one camera; IDAS-2 is corresponding two cameras.

●Measurement items can be stored up to max.50 points, displayed any 5 points.

●Failed image data (bmp format), measurement data/statistical data (CSV format) to be stored.

●The most recent failed time and failed image to be showed at real-time.

●Viewing as a trend chart or histogram graph for inspection data.

Most recent failed images are saved up to max.10,000 frames per lot.

Most recent failed images are saved up to max.10,000 frames per lot. Measurement data can be saved up to max. 999,999 records per lot.Measurement items can be stored up to max.50 points.

Measurement data can be saved up to max. 999,999 records per lot.Measurement items can be stored up to max.50 points. Statistical data records for per lot can be saved to maximum (most recent) 1,000 records.Statistical data is to be included maximum, minimum, averages and standard deviations, for each measurement item.Furthermore, the statistical data storage folder can also saves statistical data charts for the most recent 1000 lots.

Statistical data records for per lot can be saved to maximum (most recent) 1,000 records.Statistical data is to be included maximum, minimum, averages and standard deviations, for each measurement item.Furthermore, the statistical data storage folder can also saves statistical data charts for the most recent 1000 lots.Unwinding Machines

AUTO TURNTABLE

AUTO TURNTABLE T Series

AUTO TURNTABLE TL Series

TRAVERSER TR-963

NC Grip Feeders NCG65SA

Winding Machines

HORIZONTAL AUTOMATIC WINDER MHA...

HORIZONTAL AUTOMATIC WINDER MHA...

MULTI-LAYER SPIRAL REEL WINDER...

Automatic Bin Changer CASELINER...