Features

Multiple Blanking functions to improve work efficiency while ensuring safety

Through safe design and specifications compliant with international standards, we have exhaustively pursued higher levels of safety and realized higher work efficiency. This direct-projection safety device for press machines can be flexibly adapted to various work content and enables dramatically improved work efficiency

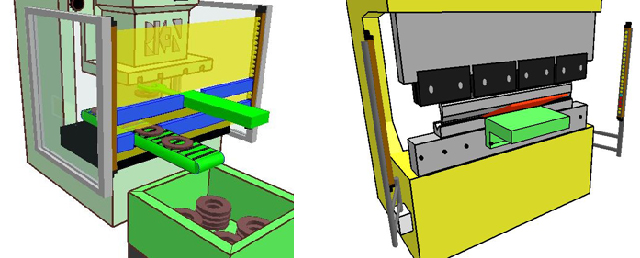

Fixed blanking functions and Floating blanking function to improve work efficiency while ensuring safety

When a stationery object (e.g., device or material) is blocking certain beams during normal operation, these beams can be deactivated to enable operation of the press.

Function

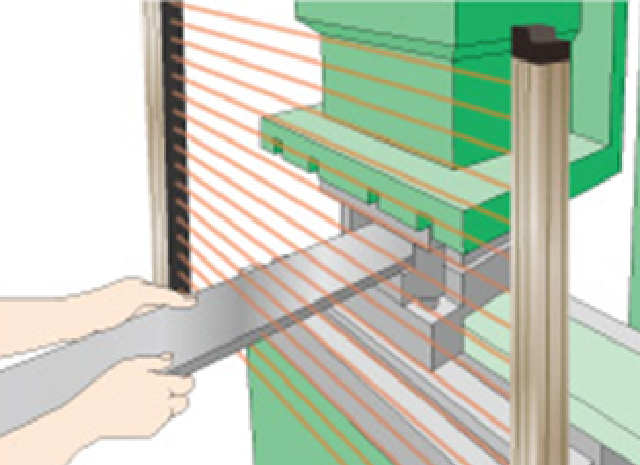

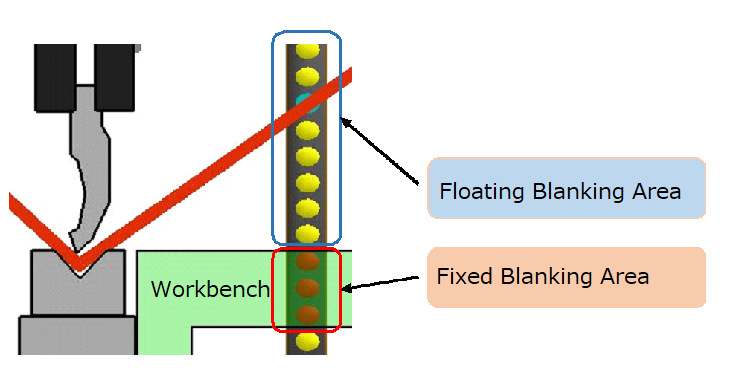

Floating blanking

In normal sensor operation, a signal to stop the press is output if one beam is blocked, but using this function, a stop signal is only sent when two or more beams are blocked. This is useful when it is necessary to move objects in the sensor monitoring area

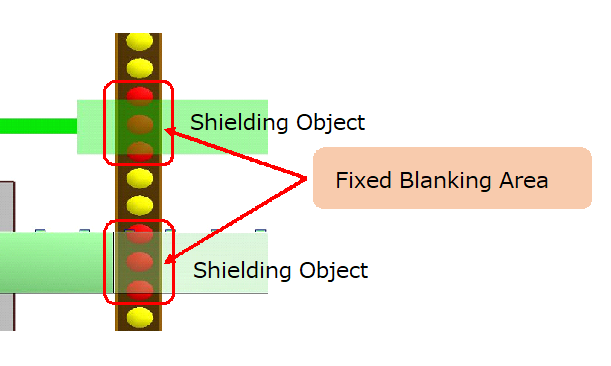

Fixed blanking

When a stationery object (e.g., device or material) is blocking certain beams during normal operation, these beams can be deactivated to enable operation of the press.

* A special controller is required to use the blanking functions.

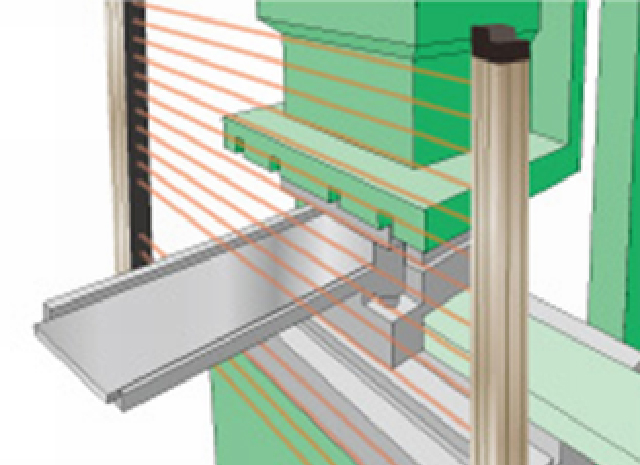

Combination of Fixed Blanking and Floating Blanking

In addition to the fixed blanking function, there is a built-in dual optical axes blanking (floating) function. When multiple areas of beams are interrupted by obstacles(part of facility, materials and workpieces),combined use of two types of blanking function deactivate the interrupted beams and realize the efficient press operation without losing safety.

3 modes of Blanking Function

1. Fixed Blanking Mode

Multiple optical-axes interrupted area can be set as blanking area (up to 5 areas)

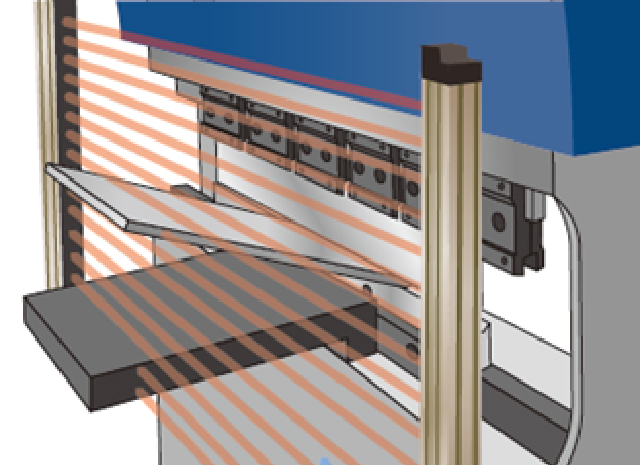

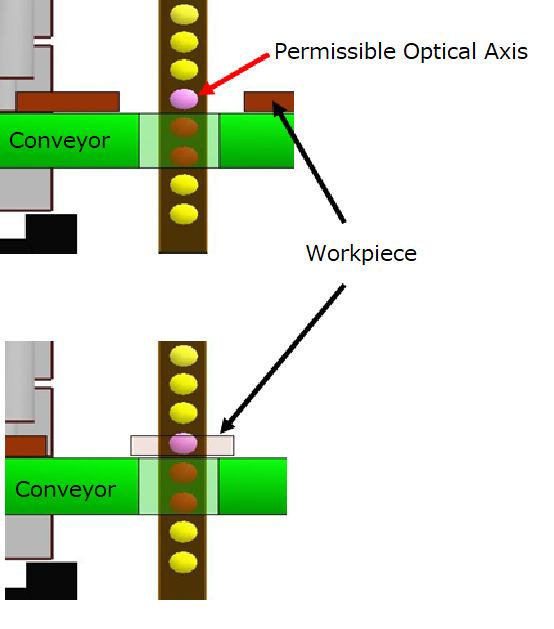

2. Fixed blanking mode with permissible optical axis

It is possible to move the monitoring area up to ± 1 optical axis above or below the fixed blanking setting area.

*When using allowable optical axis function

- To prevent influence of passing through of the materials and workpiece

- To prevent influence of shaking of the feeder or the conveyor by vibration of the press machine

Even in the above case, It is possible to continue work without interference when blocking certain beams within the permissible optical axes range.

3.Combination of Fixed Blanking and Floating Blanking

When part of the equipment or workpiece is present in the sensor monitoring area, safe work is possible by blanking setting the corresponding area optical axes. It can correspond not only to fixed parts but also to movable parts.

Here is the point !

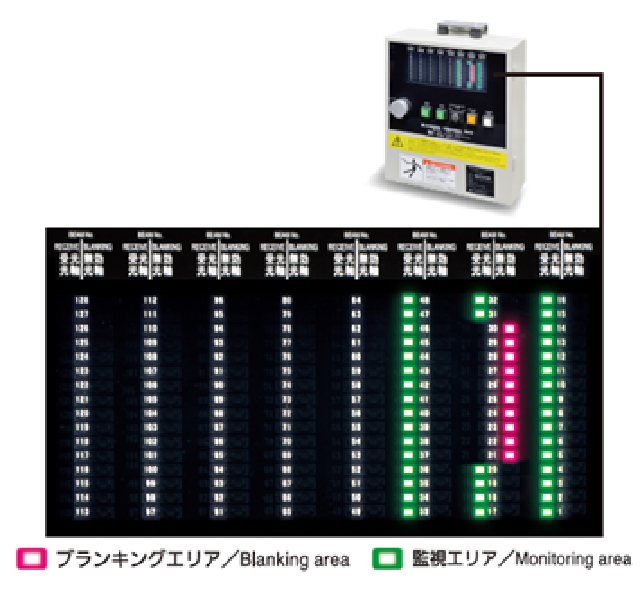

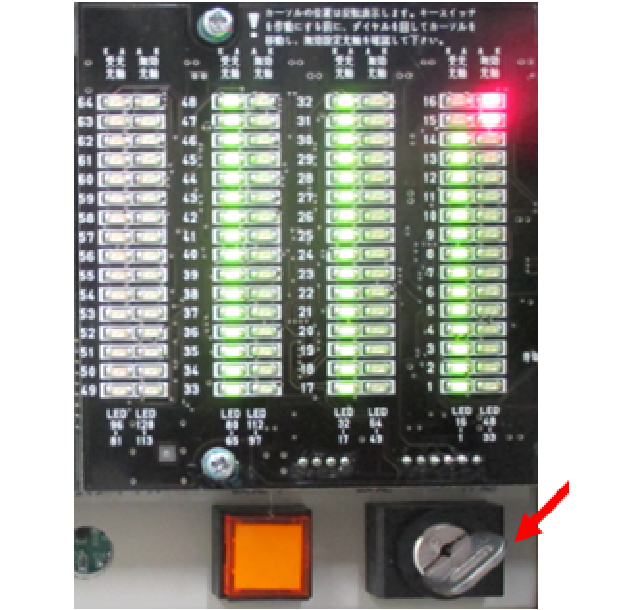

Visualize monitoring area and blanking area with LED display of dedicated control box

The front panel of the Blanking dedicated control box shows the state of the sensor’s total optical axes.

The LED display can grasp which part of the area is set blanking at a glance.

Blanking area easy to setup

Easy blanking is possible by using only the key switch in the dedicated control box.

*Regarding the blanking setting key, please manage by the administrator such as press

work chief administrator.

Three types of blanking function enable safe and efficient work

- Fixed blanking function

- Fixed blanking function using allowable optical axis

- Blanking function combined protection with floating function

*Setting of mode can be easily changed by using the control box.